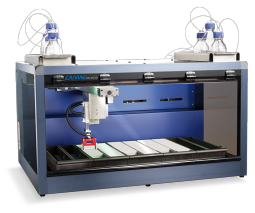

Key features:

- High throughput analysis of up to 500 DBS cards per run

- Integrated optical card recognition and barcode reading module

- Automated internal standard application module

- Unique extraction module with wash station to eliminate carry-over

- Online coupling to analysis system (LC-MS, MS or Sample Collector)

- Full control through Chronos software

The fully automated CAMAG DBS-MS extraction system makes DBS analysis remarkably easy and has strong advantages compared to both the manual and semi-automated punching techniques. With the CAMAG DBS-MS 500 extraction procedure DBS analysis is an economical alternative to conventional blood sampling. It represents a time- and cost-saving technique for analyzing pharmacological samples and is less invasive for participants or animals.